Explore the characteristics and industrial applications of laser welding machines

Laser welding technology has transformed manufacturing processes across multiple industries by offering precision, speed, and versatility. This advanced joining method uses concentrated laser beams to fuse materials with minimal heat-affected zones, making it ideal for applications requiring high-quality welds. Understanding the core characteristics and industrial applications of laser welding machines helps businesses evaluate whether this technology aligns with their production needs and quality standards.

Learn About Laser Welding Technology

Laser welding technology operates by focusing a high-intensity laser beam onto the workpiece surface, generating localized heat that melts and fuses materials together. The process can be performed using continuous wave lasers or pulsed lasers, depending on the application requirements. Continuous wave lasers maintain a steady beam output, making them suitable for deep penetration welding and high-speed operations. Pulsed lasers deliver energy in short bursts, providing better control over heat input and reducing thermal distortion in thin materials.

The two primary laser types used in welding are fiber lasers and CO2 lasers. Fiber lasers have gained popularity due to their superior beam quality, higher electrical efficiency, and lower maintenance requirements. They excel at welding reflective materials like aluminum and copper. CO2 lasers, while older technology, still find use in certain applications requiring deeper penetration or working with thicker materials. The choice between laser types depends on factors such as material composition, thickness, production volume, and desired weld characteristics.

The Main Features of Laser Welding Machines

Laser welding machines offer several distinctive features that set them apart from traditional welding methods. Precision stands as one of the most significant advantages, with laser beams focused to spot sizes as small as a few micrometers. This precision enables welding of intricate geometries and small components without affecting surrounding areas. The concentrated heat input creates narrow weld seams with minimal distortion, reducing the need for post-weld finishing operations.

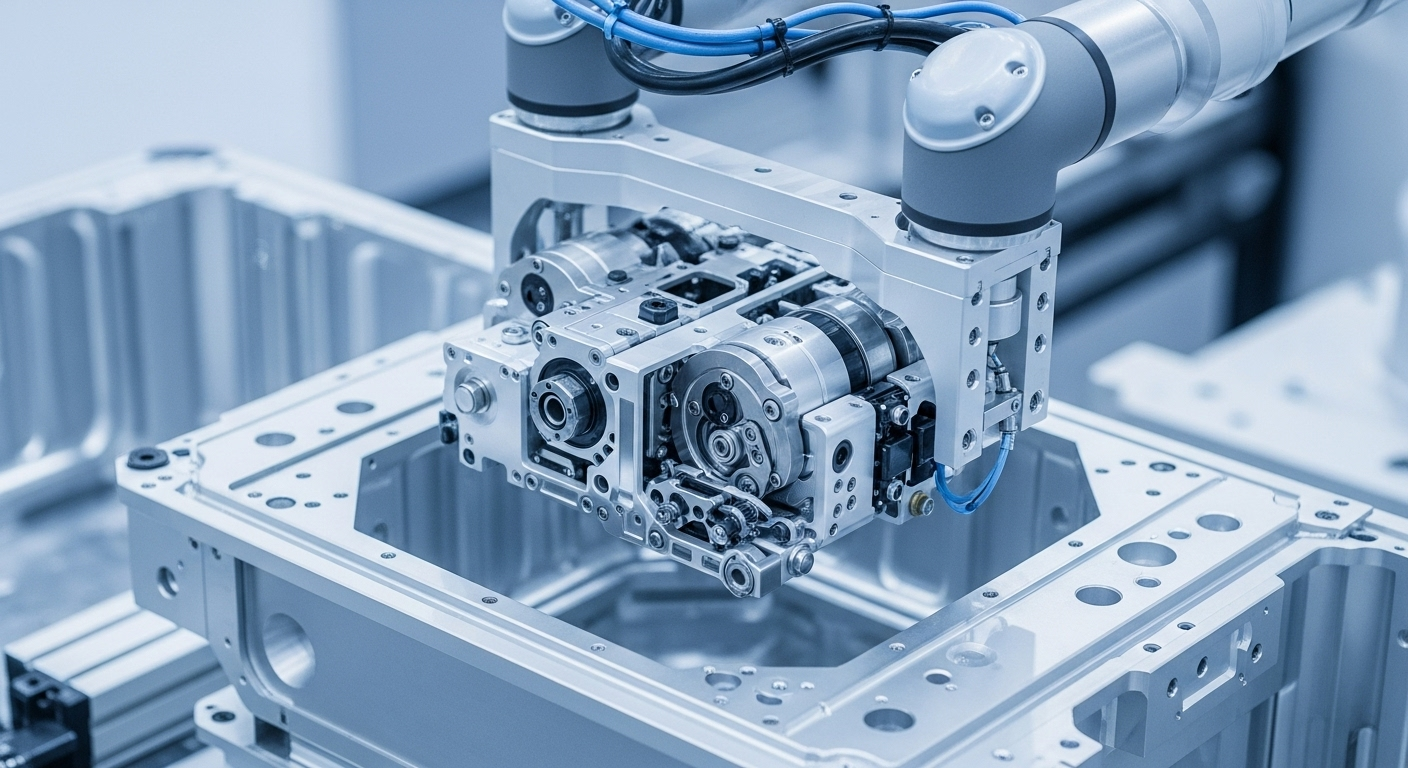

Speed represents another key feature, as laser welding processes operate significantly faster than conventional methods like TIG or MIG welding. High-power fiber lasers can achieve welding speeds exceeding several meters per minute, dramatically increasing production throughput. The non-contact nature of laser welding eliminates tool wear and allows for automated operation with minimal human intervention. Modern laser welding systems integrate seamlessly with robotic arms and computer numerical control systems, enabling consistent quality across large production runs.

Versatility in material compatibility extends the usefulness of laser welding machines across diverse applications. These systems can weld various metals including stainless steel, carbon steel, titanium, nickel alloys, and dissimilar metal combinations that prove challenging with traditional methods. The ability to join different materials opens possibilities for lightweight construction and multi-material assemblies in automotive and aerospace applications.

Industrial Applications of Laser Welding

The automotive industry represents one of the largest adopters of laser welding technology. Manufacturers use laser welding for body-in-white assembly, where multiple sheet metal components are joined to form the vehicle structure. The precision and speed of laser welding enable the creation of lighter vehicles with improved fuel efficiency without compromising structural integrity. Battery pack assembly for electric vehicles increasingly relies on laser welding to join battery cells and create hermetically sealed enclosures that protect sensitive components.

Aerospace applications demand the highest quality standards, making laser welding an ideal choice for joining critical components. Aircraft engine parts, turbine blades, and structural elements benefit from the clean, precise welds that laser technology produces. The reduced heat-affected zone minimizes material property changes, maintaining the strength and fatigue resistance required for aerospace applications. Medical device manufacturing utilizes laser welding for creating sterile, biocompatible joints in surgical instruments, implants, and diagnostic equipment.

Electronics and microelectronics industries employ laser welding for assembling small components where traditional welding methods prove impractical. The technology enables the joining of delicate parts in smartphones, sensors, and battery connections without thermal damage to nearby sensitive elements. Jewelry manufacturing has also adopted laser welding for repair work and creating intricate designs with minimal material loss and excellent aesthetic results.

Future Trends in Laser Welding

The evolution of laser welding technology continues with advancements in power output, beam control, and process monitoring. High-power fiber lasers exceeding 20 kilowatts are becoming more accessible, enabling single-pass welding of thicker materials and faster production speeds. Beam shaping technologies allow operators to modify the laser beam profile dynamically, optimizing heat distribution for different joint configurations and material combinations.

Artificial intelligence and machine learning integration represents a significant trend shaping the future of laser welding. Smart welding systems equipped with real-time monitoring sensors can detect defects during the welding process and automatically adjust parameters to maintain quality. Predictive maintenance algorithms analyze machine performance data to schedule maintenance before failures occur, reducing downtime and extending equipment lifespan.

Green manufacturing initiatives drive the adoption of laser welding due to its energy efficiency and reduced material waste compared to traditional methods. The precise nature of laser welding minimizes the need for filler materials and post-processing operations, lowering overall environmental impact. As industries face increasing pressure to reduce carbon footprints, laser welding technology positions itself as a sustainable solution for modern manufacturing challenges.

Hybrid welding processes combining laser technology with other methods like arc welding are gaining attention for applications requiring both deep penetration and gap bridging capabilities. These hybrid approaches leverage the strengths of multiple technologies, expanding the range of materials and joint configurations that can be successfully welded. Research continues into new laser wavelengths and pulse patterns that could further enhance welding performance across diverse materials and applications.

Conclusion

Laser welding machines have established themselves as essential tools in modern manufacturing, offering unmatched precision, speed, and versatility across numerous industries. The technology’s ability to produce high-quality welds with minimal thermal distortion makes it particularly valuable for applications demanding tight tolerances and structural integrity. As laser systems become more powerful, efficient, and intelligent, their adoption will likely expand into new sectors and applications. Understanding the characteristics and capabilities of laser welding technology enables manufacturers to make informed decisions about integrating this advanced joining method into their production processes, ultimately improving product quality and operational efficiency.